Business

Approach

Sakamoto Tool and Die has an enviable record of success in manufacturing products used in a wide range of fields, form products for household use to medical equipment to sophisticated communication devices to automobile parts.

We are proud of what we have achieved to date.

We intend to surpass what we have already done. Our intent is to quickly understand our customers' needs and to respond rapidly with the products they require.

We have a sales force whose mission is to identify what our customers need and get that message back to our production managers.

A company organization built around project teams is designed to promptly respond to those customer requirements.

Two modern production facilities --our headquarters and main plant in Osaka and our state of the art Shiga factory - are closely linked and work as an efficient team that gives our company both the flexibility and the know-how to move quickly from the design stage to the production process.

How can we produce what the customer wants and how can we do that in the shortest amount of time?

Our personnel and our installations have only one mission: to stay in the lead in our industry by working together as creatively and efficiently as possible.

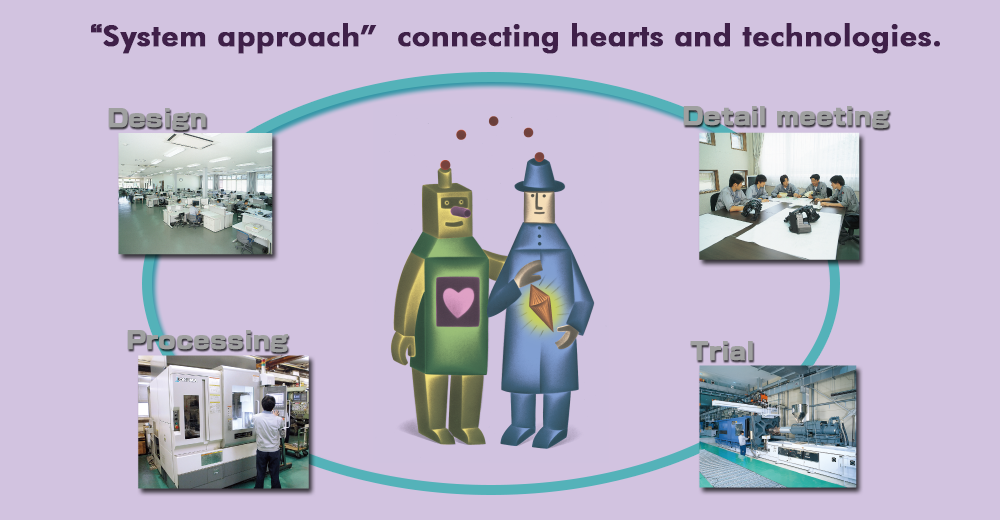

At Sakamoto Tool and Die we take a systematic approach to engineering.

DSI molding

The Actual Products Tell Our Story Best

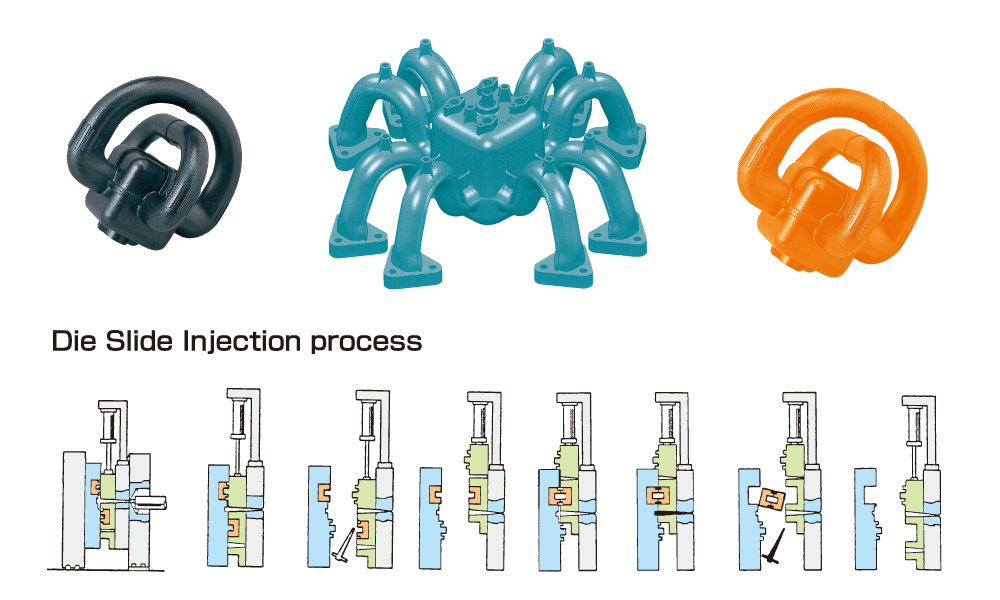

The illustrations on left page show products made in molds that have a complex structure. This seamless production of products that once had to be done as multiple parts as long been a goal of engineers. But the barriers to this type of production were high. Despite these barriers our engineers persisted in their effort to develop new production methods based on technology that had not been employed until now. The results are products which serve the needs of our customers better than what was offerd in the past. Ultimately, the customer benefits from the innovations which we have brought to the mold-making process, what we call "Integral Hybrid Molding Technology."